One-Stop Mold Manufacturing, Surface Finishing & Secondary Processing

As a leading China precision plastic injection mould factory, we provide a comprehensive one-stop solution for custom mold manufacturing, advanced surface finishing, and secondary processing. From design to final product, our integrated services help you avoid managing multiple unverified suppliers, minimizing quality risks and maximizing efficiency.

Secondary Processing & Assembly Services

We help our clients manage a wide range of secondary processes, including:

- Oil Painting: Professional oil painting for plastic and metal parts, offering vibrant colors and durable finishes.

- Silk-Screening: Highly specialized process for printing on flat and flexible plastic surfaces, ideal for logos and graphics.

- Laser Marking & Engraving: Fast, permanent, high-resolution marking for words, patterns, and anti-counterfeiting features on plastics and metals.

- Electroplating: Using electrodeposition to coat objects with metal for corrosion protection, decorative effects, wear resistance, and tailored electrical properties (conductive or insulating coatings).

- Fabric Wrapping (Heat Pressing): Advanced heat pressing technology to wrap fabric securely around plastic covers, enhancing aesthetics and functionality.

- Ultrasonic Welding: High-frequency sound waves weld plastics precisely and efficiently, saving energy and ensuring strong, reproducible joints without adhesives.

- Assembly: From part production to final assembly, we deliver ready-to-use products, reducing your supply chain complexity.

Advanced Surface Finishing

- Bead Blasting: Matte, uniform finish for improved appearance and wear resistance.

- Anodizing: Electrolytic passivation for corrosion and wear resistance, available in multiple colors.

- Polishing: Manual or mechanical for glossy, smooth surfaces.

- Powder Coating: Durable, colorful, and protective finishes for metals.

- Brushing: Satin finish for enhanced visual appeal.

- Black Oxide & Alodine: Specialized coatings for corrosion resistance and base layers.

- Part Marking: Logos and custom lettering for identification and branding.

- Additional Treatments: Chemical milling, shot peening, laser marking, electroless plating, conversion coating, and more.

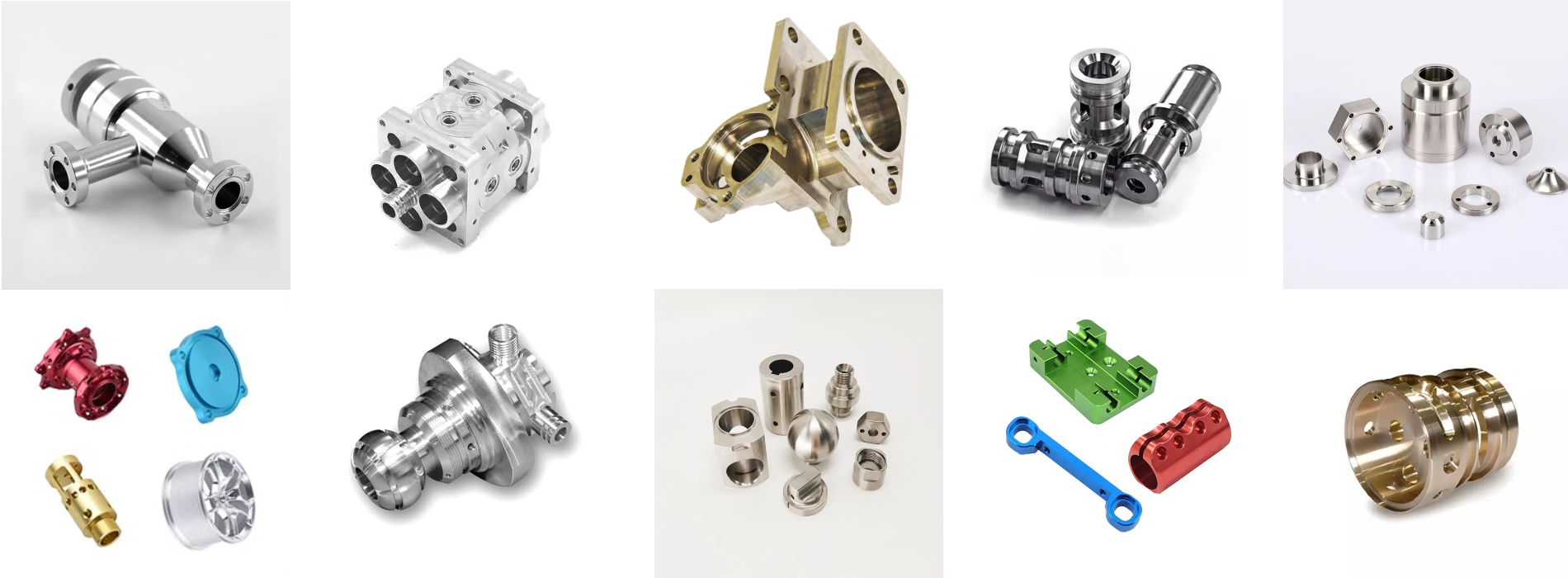

Metal & Plastic Surface Finishing

- Mechanical Finishing: Grinding, polishing, sandblasting, vibratory finishing.

- Electrochemical Finishing: Anodizing, electroplating, electropolishing.

- Coatings: Powder coating, PVD/CVD, zinc flake coating.

- Chemical Treatments: Passivation, black oxide.

- Emerging Technologies: Laser texturing, nanocoatings, cold spray.

Plastic-Specific Finishing

- Coatings: Painting, vacuum metallization, in-mold decoration.

- Chemical Treatments: Etching, electroplating.

- Mechanical Finishing: Laser engraving, polishing.

- Advanced Techniques: Plasma treatment, 3D texture printing, conductive coatings.

Eco-Friendly & Innovative Solutions

- Biodegradable coatings, dry lubricants, smart surfaces (self-healing, thermochromic/photochromic).

Why Choose Us?

- All-in-one service: From mold design, injection molding, secondary processing, to surface finishing and assembly.

- Minimize quality risks and simplify your supply chain.

- Advanced technology and strict quality control ensure superior results.

- Customized solutions for various industries, including automotive, electronics, medical, and consumer goods.

Selection Guidelines

Select the optimal surface treatment and secondary process based on your requirements for functionality, aesthetics, cost, and sustainability. Our expert team ensures compatibility with your material and application needs.