High-Quality Dimensional Inspection Service

At HKY-Technik, we provide high-quality dimensional inspection services to deliver the most accurate and reliable measurement results for our clients. By leveraging advanced laser scanning and industrial CT scanning technologies, combined with state-of-the-art 3D inspection software, we guarantee the authenticity and precision of every dimensional report.

Technical Principles

- Laser Scanning: Utilizes laser beams to rapidly capture the 3D surface data of objects, generating dense point clouds and highly accurate 3D models. This non-contact method is fast, precise, and ideal for complex shapes and surfaces.

- Industrial CT Scanning: Based on X-ray penetration, CT scanning reconstructs detailed 3D images of both internal and external structures without damaging the sample. It achieves micron-level accuracy and is perfect for complex or high-precision components.

Advantages & Features

- Authentic Data Assurance: We understand the importance of genuine measurement data. Our advanced technology and strict quality control ensure every report is accurate and reliable, with zero tolerance for falsification.

- High-Precision Measurement: Both scanning methods achieve micron-level accuracy, capturing even the smallest dimensional deviations, fully meeting the needs of precision-critical products.

- Comprehensive Inspection: Our technology covers both external and internal dimensions, ensuring no blind spots and preventing overlooked issues in complex structures.

- Non-Contact Measurement: No physical contact is required, preventing damage or deformation—especially suitable for delicate, soft, or easily scratched surfaces.

- Fast & Efficient Process: Rapid data acquisition and efficient software analysis significantly reduce inspection cycles and deliver timely results.

- Intuitive Reports: Advanced 3D visualization presents results as clear graphics, charts, and color maps, enabling clients to easily understand dimensional deviations and make informed improvements.

Application Scenarios

- Automotive Manufacturing: Full-body and component inspection for assembly accuracy and quality assurance.

- Aerospace Industry: High-precision measurement and tolerance analysis for aircraft structures and engine parts.

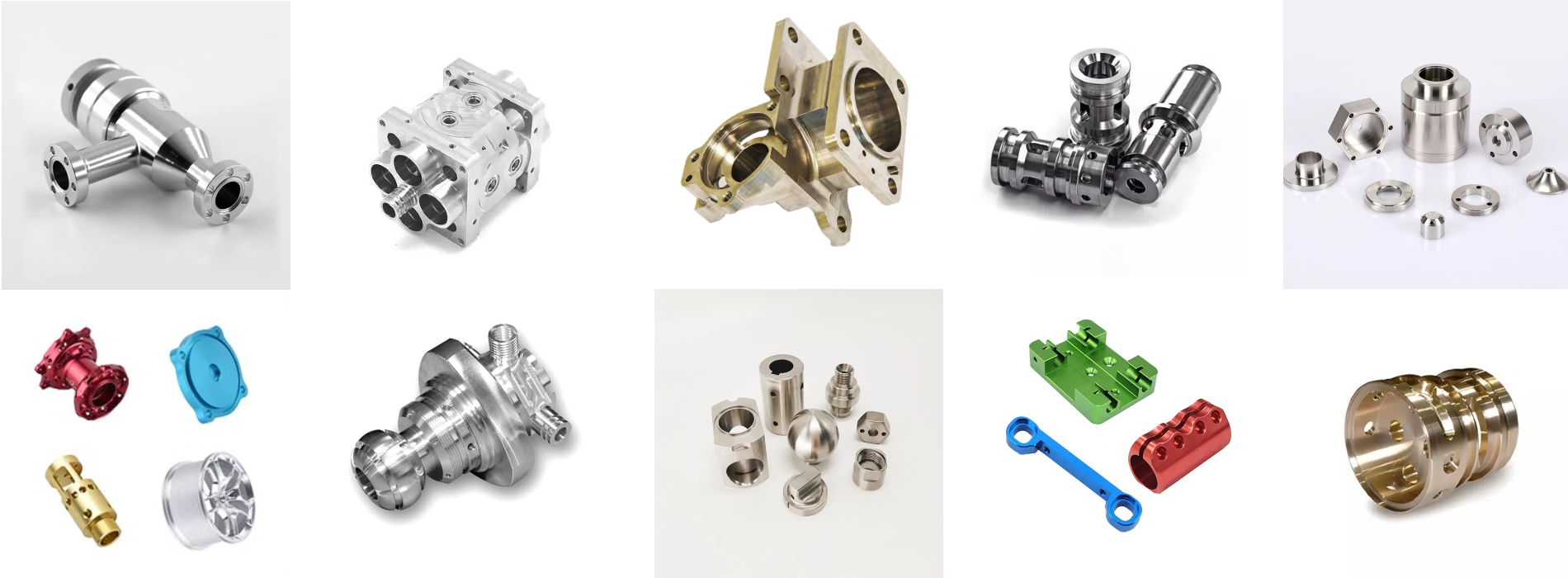

- Machining Industry: Inspection of shafts, sleeves, plates, and other precision parts to ensure conformity and improve yield.

- Electronics Manufacturing: Dimensional analysis of electronic components and PCBs for assembly and electrical performance.

- Cultural Heritage Protection: 3D scanning for digital preservation and restoration of artifacts.

Service Process

- Client Consultation: Understand product type, inspection goals, key dimensions, accuracy requirements, quantity, and delivery timeline.

- Quotation & Contract: Tailored inspection plan and transparent pricing, followed by contract signing.

- Product Preparation: Clients prepare and deliver samples, or we arrange on-site collection.

- Scanning & Data Processing: Professional operators perform scanning and data preprocessing for optimal quality.

- Measurement & Analysis: Using 3D software, we carry out precise measurements and compare results with design models or standards.

- Report Compilation & Review: Detailed reports include product info, methods, data, deviation analysis, and improvement suggestions, all strictly reviewed for quality.

- Report Delivery & Interpretation: Reports are provided in both digital and hard copy, with technical support for interpretation if needed.

- After-Sales Support: Responsive service for any questions or further analysis, with continuous improvement based on client feedback.

Case Studies & Data Support

Electronics Connector Inspection: Laser scanning identified pin pitch and shell thickness inconsistencies, ensuring production quality and customer satisfaction.

Automotive Engine Block Inspection: Combined laser and CT scanning revealed and resolved issues with bore deviation, hole spacing, and flatness, enhancing product quality and competitiveness.

Aerospace Blade Inspection: Industrial CT scanning detected chord length and twist angle deviations, supporting quality improvement.

After FOT, the actual test data can be to meet the tolerance, the approximately 95% of the molds can pass the trial on T2.