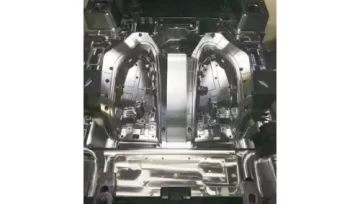

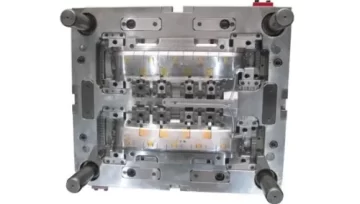

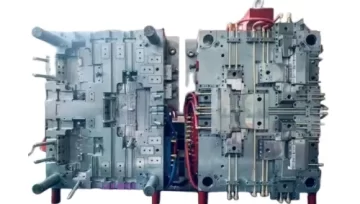

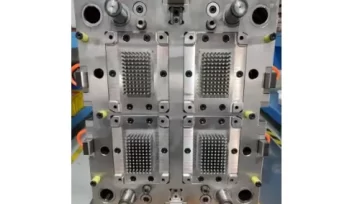

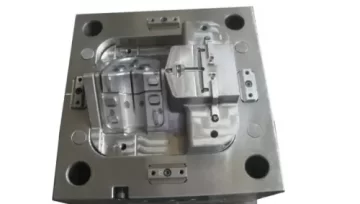

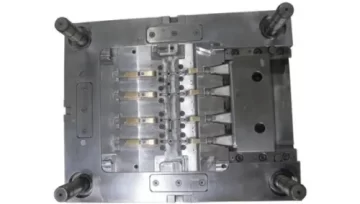

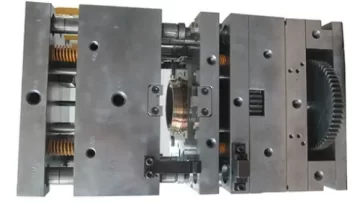

As a leading China precision plastic injection mould factory, we specialize in high-precision mold component manufacturing, leveraging advanced CNC machining, Wire EDM, EDM, and grinding technologies. Our state-of-the-art equipment and experienced team ensure superior quality, fast turnaround, and reliable solutions for global clients in automotive, medical, and electronics industries.

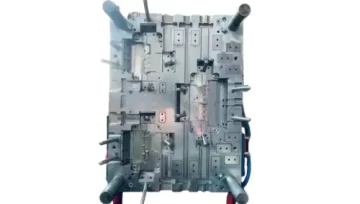

Core Machining Capabilities

Precision CNC Machining

We operate a fleet of advanced CNC machines, including:

- Li-young V10 (1200×750×700mm, ±0.005mm)

- Ji Li Xing V3 (1100×700×600mm, ±0.005mm)

- Mitsubishi VIC1060 (2 units, 1200×700×700mm, ±0.01mm)

- Hardford LG860 (1100×700×600mm, ±0.005mm)

- OHIC OH-650 (600×500mm, ±0.005mm)

- Haitian GLUe16X25 (2500×1500×700mm, ±0.01mm, capable of machining 3mm components)

- AFHIG HSC-1100 High Speed Machining Center (1050×650×550mm, ±0.005mm)

- Jiatje (450×400×320mm, ±0.1mm, 2 units)

Our CNC centers deliver micron-level accuracy for complex mold bases, cores, and inserts, supporting high-volume and high-complexity projects.

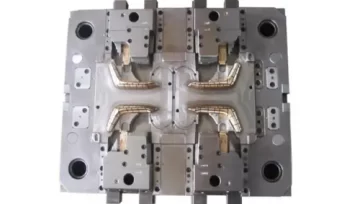

Slow Wire EDM (Wire Cutting)

For intricate features and sharp internal corners, our Wire EDM section is equipped with:

- Han Sparke HG200 Double Head Mirror EDM (3500×1800×1600mm, ±0.01mm)

- Diamond & Spark BE30 Mirror EDM (500×400×300mm, ±0.005mm)

- Han Sparke HE80 Mirror EDM (1100×800×600mm, ±0.005mm)

- Han Sparke HE150 Mirror EDM (2000×1300×1000mm, ±0.005mm)

Wire EDM ensures exceptional precision for mold inserts and complex cavity shapes that are otherwise impossible with conventional machining.

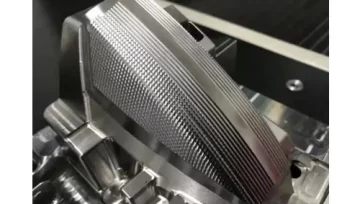

EDM Machining (Electrical Discharge Machining)

Our EDM workshop is equipped with industry-leading machines for processing hardened steels and complex geometries, delivering fine details and undercuts essential for advanced mold designs.

Precision Grinding

To achieve ultra-smooth finishes and exact dimensions, we utilize:

- Mitoyo Grinding Machines (6 units, 550×350×400mm, ±0.005mm; 400×200×300mm, ±0.005mm)

Precision grinding is critical for ensuring the longevity and performance of injection molds in demanding production environments.

Additional Equipment & Capabilities

- Mold-Fitting Machine: Shi Yi LS-120 (1500×1200×1000mm)

- Laser Engraving: Xin Guang Yuan XGY-MF22W (600×600mm)

- Lathe: Yun Ji (C6132×750, C6240×1000, ±0.02mm)

- Injection Molding Machine: Haitian (120T, 250T)

- Temperature-Controlled Cabinet: 24 Groups

- OHII: Si Rui SW2515 (250×150×200mm, ±0.002mm)

- CMM (Coordinate Measuring Machine): Si Rui 584 (600×500×400mm, ±0.001mm)

- Cranes: 15T, 5T, 2T

Industry Trends & Innovations

- Digital Manufacturing: Integration of ERP/MES systems for real-time production monitoring and order tracking.

- Material Innovation: Use of advanced engineering plastics and high-performance steels for enhanced mold durability.

- Sustainability: Adoption of energy-efficient equipment and waste reduction practices in mold manufacturing.

Why Choose Us?

- Advanced Equipment: Full range of CNC, Wire EDM, EDM, and grinding machines from renowned brands.

- High Precision: Achieve tolerances up to ±0.001mm for critical mold components.

- Comprehensive Services: From mold design, prototyping, to mass production and quality assurance.

- Industry Expertise: Serving clients in automotive, medical, electronics, and consumer goods worldwide.

- Fast Turnaround: Streamlined production and digital management ensure on-time delivery.

Conclusion

Our China precision plastic injection mould factory is your trusted partner for high-precision mold components. With a world-class equipment lineup and a skilled team, we deliver superior quality, efficiency, and value to every project. Contact us today for your next mold manufacturing requirement.